I'm stranded at the John Wayne airport giving me the time to do a quick update. Gotta love commercial airlines...

After noticing that the cowl would not line up the same every time it was installed, I decided to patch the holes in it. Lots of openings from previous systems allowing the cowl to flex.

After reviewing the oil cooler installation, I decided to rework it again. The angle of the cooler made for a terribly inefficient system. There is just no more space to work with and will give me the opportunity to fix the sharp curve at the firewall.

The oil cooler was a 13 row Mocal cooler that was 13" wide and 4" tall. I decided to go with a Positech cooler that had about the same fin area but was only 8" wide.

I mocked the new shape up in Photoshop using a 10 row cooler but it was still too wide. The green line is the shape of the bottom of the cheek. I dropped it a bit to allow the hot air exiting the heads a more direct path to the cooling outlet. The red line would have been the overall shape of the lower cowl and the blue would have been the new outlet duct.

I was still not happy with how it was going to work out and went with a Positech cooler for an O-300. Its only 8" wide and will not force the bottom of the cowl to be quite as low. Being on the road, I used an iPad app called Touchdraw to mock it up. Its one of the better CAD apps and allows photo imports. It supports layers and opacity settings that allow for the creation of ghost images.

Now if I could only get home to actually do the work!

Random offerings of nothingness negated by actual reality.

Friday, January 24, 2014

Wednesday, January 15, 2014

Cowl Flange

To create the flange that maintains the duct shape and matches the baffle, I used the inside of the baffle as the mold. After trimming the aluminum baffle flush with the rough opening of the inlet, I taped off both the inlet and the cowl with tape and then waxed it for a mold release.

I made the layup in multiple stages. Since this was the case, I used West Systems epoxy so that did not need to sand it between layers. This could have been done with vinylester but I wanted a long working time to make sure things were right. The first step was to glass the corners with glass cut on a bias.

After the corners were mostly cured (using a radiant heater to speed the setup), I went back and glassed the sides, top and bottom.

Using an Exact knife, I trimmed the the fringe back flush with the cowl.

The next step was to create a reference flange so that I could line things up in the same location once the cowl was off. For this I used a lighter glass cut on a bias so that it would follow the sharp curve of the cowl. I used polyester resin for this step to speed up the cure time.

After it all set up, the cowl and baffle were remove and this is the result.

Next step is to put the cowls together off of the airplane and glass the flange into place from the inside of the cowl using the reverence flange to align everything. From there the flange needs to be trimmed to its final size and the aluminum baffle needs to be cut back to meet it.

Sunday, January 12, 2014

Why keep tearing apart a perfectly good airplane?

(skip to the end if you don’t care and just want to see the

baffle progress ; )

Its been 18 months since the Skye Racer last flew and one

might ask “why do you keep tearing a perfectly good airplane apart?” Speed

right? Not actually. It’s about learning…

I love to learn new things. I enjoy digging into how things

work and solving problems. My long term goal is to use what I learn and design

cool airplanes. I have been working on a two seat design on and off with the

help of my friend Ed Fisher for a few years.

That may shed some light on why I not only tear it apart

constantly, but is also why I do things three or four times even though the

earlier attempts could have been considered acceptable. I have no interest in

building show winning airplanes. They can’t look like crap, but I must confess,

I don’t always perfectly space rivets where it does not matter ; )

A Sonerai is a perfect platform for this type of

experimentation and learning. It’s a forgiving airplane with a relatively slow

stall speed and fairly large tires, just in case one of the experiments goes

wrong. With the VW engine, it’s inexpensive to make changes to. Even with

ported and polished racing heads, a complete top overhaul is about $800. A cam

is about $100 with hundreds to choose from. If you want to raise or lower the

compression, its $10 for a new set of cylinder shims.

Turbo Sonerai Project

When this latest project began it did not include

turbocharging. I was designing a tuned intake manifold, 4-1 exhaust and looking

for a new carb. I also wanted to reduce cooling drag which is why I extended

the nose of the airplane. Turbocharging only came into the picture after I

realized that a tuned intake manifold and exhaust required a lot of space. While

I have often referred to it as the “Turbo Sonerai” project, that’s not how it

began.

With cooling drag reduction being one of the primary goals,

I was not willing to rush the cooling baffles to make the 2013 Airventure Cup

race. I had worked too hard on the cowl to make more space available to slop

something together.

Back To the Baffles

The goals for the new baffles were simple. They had to have

no leaks and be easy to remove and install. The shape had to be as efficient as

I could make it within the available space. My last set of baffles sealed and

cooled the engine well, but they were horribly draggy. The required stupid

amounts of silicone to hold them on and seal them. They took about 2 hours to

remove and install, mostly because of the amount of old silicone that had to be

removed. After they were reinstalled I had to wait for the silicon to set up,

which would take hours.

I had originally intended on making another set of composite

baffles using poured urethane foam as a plug. With a week or two left before

the race, I thought I could get them done in time, but I was out of epoxy and

did not want to make a huge mess with the foam and glass process. I thought I

could get them done easily out of aluminum. I leaned that while I was a

competent with typical A&P type sheet metal tasks, my experience and

available tools were not up to the task of quickly making the kind of baffles I

wanted.

After an estimated 80 hours, I am finally almost done with

the first side. The upside is that I learned a lot and now have a baffle that

seals with nearly no silicon can be removed and reinstalled in 10 minutes.

That brings me up to today. There was one part of the baffle

that I resorted to using composites. It was a compound shape caused by the need

to stay out of the way of the intake tube coming off of the turbo. I tried to

meet my design goals with aluminum three times and was not willing to start

banging on metal with a hammer and sand bag. I gave up and went the plastic

route.

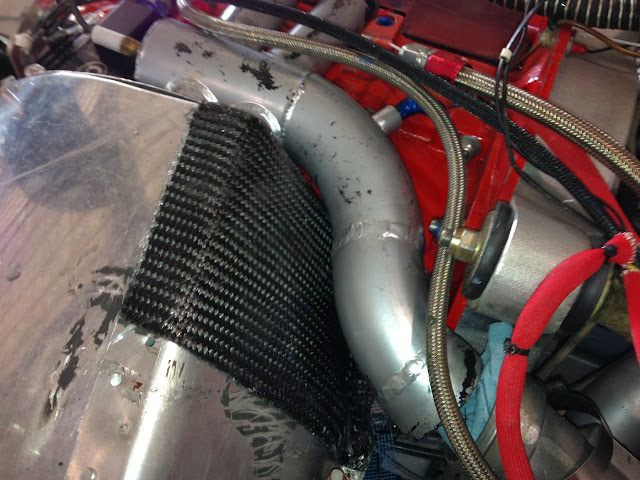

To make the part, I used wire mesh to conform to the inside

of the baffle and covered it with aluminum tape. I smeared it with silicone to

fill in any weird spots and act as a mold release. I then covered the area with

2 layers of heavy carbon fiber. Its still needs to be trimmed and attached but

at least the shape is done!

Next up is to create a lip for the cooling inlet and come up

with some type of perfect seal between it and the baffle while still

maintaining the effectiveness of the divergent duct.

I started on the other side while waiting for the hanger to

warm up enough to do a layup. The other side is going to be much faster!

Wednesday, January 8, 2014

Getting Back to Work!

The cooling baffles are moving forward finally!

Cutting and fitting these shapes out of aluminum is not fun. If I was starting from scratch today they would have been made out of glass. I started the aluminum baffles a week before the Airventure Cup race and was out of epoxy with no local source. For better or worse, this rendition will be aluminum.

Cutting and fitting these shapes out of aluminum is not fun. If I was starting from scratch today they would have been made out of glass. I started the aluminum baffles a week before the Airventure Cup race and was out of epoxy with no local source. For better or worse, this rendition will be aluminum.

Subscribe to:

Posts (Atom)