In the past, I have used West Systems epoxy but when I ran out and could not find it locally I bought 3 quarts of vinylester resin. I could have used polyester, but I am getting ready to build wingtips that double as tip tanks and the vinylester will withstand fuel so I decided to give it a try.

I found it much easier to work with since it is stickier than the epoxy. When laying the glass in multiple layers at a time it held to the concave shapes much better. When using epoxy, it is a constant fight when trying to brush or squeegee resin into other parts of the layup. The vinylester kept it put even when spreading resin away from the curves (like the one aft of the spinner where the round shape joins the cheek). Its working time was just as long but it sets up much faster

which can be varied by how much MEKP you put into the resin.

The only down side is that it eats pink (or blue) foam (polystyrene). Anything that is made from it must be coated with epoxy before using vinylester over it. Oh ya, its eats the plastic cups I usually use with epoxy ; )

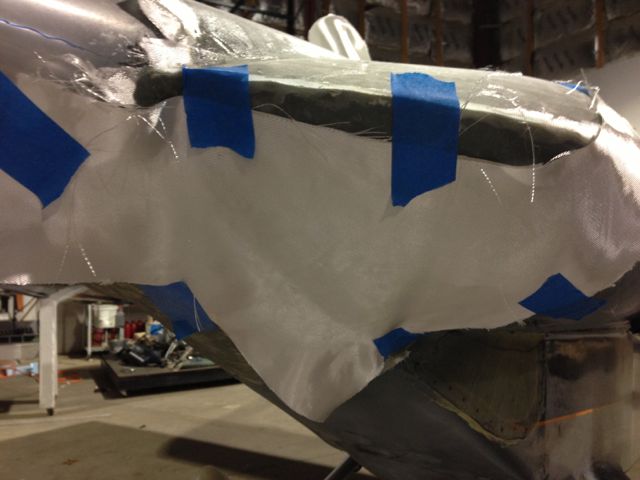

The seams are overlapping this time around. I laid 2 layers of glass across the leading edge first and then used 2 layers for the cheeks. A little peel ply (dacron fabric) was used over the edges of the glass to reduce sanding before the next layups.

After the resin has set, the peel ply is removed.

A little sanding of the edges of the glass and the bottom gets glassed. The center section that was retained from the last try will also get 2 layers for a uniform thickness.